Kód: 12738691

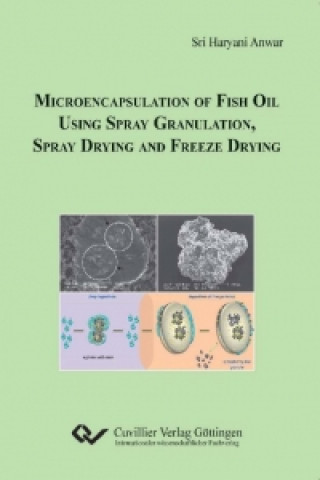

Microencapsulation of Fish Oil Using Spray Granulation, Spray Drying and Freeze Drying

Autor Sri Haryani Anwar

The stability of microencapsulated fish oil prepared using various drying methods is investigated. In the preliminary study, two production processes, i.e., spray granulation (SG) and SG followed by film coating (SG-FC) are exam ... celý popis

- Jazyk:

Angličtina

Angličtina - Väzba: Brožovaná

- Počet strán: 210

Nakladateľ: Cuvillier Verlag, 2011

- Viac informácií o knihe

Mohlo by sa vám tiež páčiť

-

Mixed-Valence Compounds

273.94 € -

Long Farewell

18.91 € -

Undocumented Students in Higher Education

145.92 € -

North Carolina

41.99 € -

Historic Road Trips from Dallas/Fort Worth

22.66 € -2 % -

Extremfälle aus der podologischen Praxis

85.60 € -

Ask Gecesi

21.44 €

Darčekový poukaz: Radosť zaručená

- Darujte poukaz v ľubovoľnej hodnote, a my sa postaráme o zvyšok.

- Poukaz sa vzťahuje na všetky produkty v našej ponuke.

- Elektronický poukaz si vytlačíte z e-mailu a môžete ho ihneď darovať.

- Platnosť poukazu je 12 mesiacov od dátumu vystavenia.

Viac informácií o knihe Microencapsulation of Fish Oil Using Spray Granulation, Spray Drying and Freeze Drying

Nákupom získate 91 bodov

Anotácia knihy

Anotácia knihy

The stability of microencapsulated fish oil prepared using various drying methods is investigated. In the preliminary study, two production processes, i.e., spray granulation (SG) and SG followed by film coating (SG-FC) are examined and compared. First, three types of fish oil (10/50, 33/22, and 18/12) based on the ratios of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) are used in the SG process. Each type of fish oil was emulsified with soybean soluble polysaccharide (SSPS) and maltodextrin to produce 25% oil powders. Second, a 15% film coating of hydroxypropyl betacyclodextrin (HPBCD) is applied to the SG granules. The powder stability against oxidation is examined by measurement of peroxide values (PV) and GC-headspace propanal after 6- weekĆs storage at room temperature (ż 21 żC) and at 3 - 4 żC. The results show that the coated powders have lower stability than uncoated powders and this indicates that the film coating by HPBCD ineffectively protected the fish oil as the coating process might have induced further oxidation. In the main research, emulsions of 33/22 fish oil are prepared with four combinations of matrices and microcapsules are produced by SG, spray drying (SD), and freeze drying (FD). The objective is to identify the most critical factors which determine powder stability and to further examine the superiority of the SG process compared to other drying processes. Oxidation parameters and analytical methods remain the same as in the preliminary study, but the storage time is extended to 8 weeks. The best matrices are a combination of 10% (w/w) SSPS and 65% (w/w) OSA-starch. Microencapsulation of 620 mg/g fish oil with these coating materials then dried by SG is able to produce fish oil powder having a very low propanal content and with a shelf life of five weeks at ż 21 żC. The ability of SSPS to form thick membranes at the oil/water interface and the role of both matrices to stabilize emulsion by steric repulsion are critical to prevent early formation of peroxides. The results of the present research indicate that instead of layering a single concentrated core, microcapsule formation by the SG process is actually started by agglomeration of seed particles. The seed particles are then covered by the growth of droplet deposition and the granule surface is coated by fine particles. This assumption is supported by scanning electron microscope (SEM) examinations which verify the raspberry-like microstructure of the final granules. Therefore, it can be assumed that the SG process produces ômultiple encapsulationsö granules and provides maximum protection to the oil droplets. Comparison of the SG, SG-FC, SD, and FD processes confirms that combination of matrices, drying temperature, microcapsule morphology, and processing time are among the most critical factors governing the stability. Exposure to high drying temperature or heat is proved to be a limiting factor for drying unstable emulsion. If a process does not apply high drying temperature, the particle morphology becomes a determining factor for product stability. The main contribution of this study is to provide in-depth evaluation of four different drying processes with comprehensive information on the drying mechanisms in relation to how they affect the stability of microcapsules. The amount of polyunsaturated fatty acids (PUFAs), fish oil quality, type of matrix, and their physicochemical characteristics are also discussed in this study.

Parametre knihy

Parametre knihy

36.22 €

- Celý názov: Microencapsulation of Fish Oil Using Spray Granulation, Spray Drying and Freeze Drying

- Autor: Sri Haryani Anwar

- Jazyk:

Angličtina

Angličtina - Väzba: Brožovaná

- Počet strán: 210

- EAN: 9783869557175

- ISBN: 3869557176

- ID: 12738691

- Nakladateľ: Cuvillier Verlag

- Hmotnosť: 279 g

- Rozmery: 210 × 148 × 11 mm

- Dátum vydania: 12. April 2011

Obľúbené z iného súdka

-

Dune

12.94 € -

Haunting Adeline

30.65 € -

Berserk Deluxe Volume 2

52.01 € -

White Nights

4.14 € -11 % -

Powerless

12.44 € -3 % -

Atomic Habits

17.40 € -24 % -

Dune Messiah

9.10 € -18 % -

Berserk Deluxe Volume 3

53.83 € -

One Day

11.02 € -23 % -

Berserk Deluxe Volume 1

44.52 € -12 % -

Iron Flame

16.28 € -18 % -

Surrounded by Idiots

11.12 € -25 % -

Harry Potter and the Prisoner of Azkaban (Minalima Edition)

27.52 € -32 % -

Gravity Falls Journal 3

21.85 € -

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 1

21.75 € -

The Creative Act

24.08 € -12 % -

Dune

12.64 € -2 % -

Hunting Adeline

31.87 € -

A Little Life

17.50 € -

Children of Dune

9.50 € -15 % -

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 2

20.33 € -4 % -

Bungo Stray Dogs, Vol. 8 (light novel)

16.89 € -

Percy Jackson and the Olympians 5 Book Paperback Boxed Set

47.25 € -

Solo Leveling, Vol. 1

21.65 € -

The Prisoner's Throne

11.43 € -4 % -

Court of Thorns and Roses

9.40 € -21 % -

Cry Baby Coloring Book

10.72 € -4 % -

Fourth Wing

14.87 € -24 % -

Icebreaker

9.40 € -15 % -

Berserk Deluxe Volume 6

47.76 € -5 % -

Avatar, the Last Airbender: The Kyoshi Novels (Box Set)

41.48 € -

The 48 Laws of Power

26.20 € -3 % -

House of Leaves

22.46 € -24 % -

Twisted Lies

9.70 € -18 % -

Dune Messiah

12.54 € -12 % -

No Longer Human

16.79 € -

48 Laws Of Power

17.80 € -24 % -

Twisted Games

9.70 € -24 % -

Caraval Paperback Boxed Set

43.10 € -

Solo Leveling, Vol. 2

19.22 € -8 % -

Open Circuits

41.48 € -

Berserk Deluxe Volume 5

53.22 € -

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 3

21.85 € -

Berserk Deluxe Volume 4

47.05 € -7 % -

Court of Mist and Fury

9.30 € -21 % -

SOLO LEVELING V08

21.65 € -

English File Upper Intermediate Multipack A (4th)

19.42 € -12 % -

CHAINSAW MAN V14

11.22 € -13 % -

Before the Coffee Gets Cold

9.70 € -24 %

Osobný odber Bratislava a 2642 dalších

Copyright ©2008-24 najlacnejsie-knihy.sk Všetky práva vyhradenéSúkromieCookies

21 miliónov titulov

21 miliónov titulov Vrátenie do mesiaca

Vrátenie do mesiaca 02/210 210 99 (8-15.30h)

02/210 210 99 (8-15.30h)